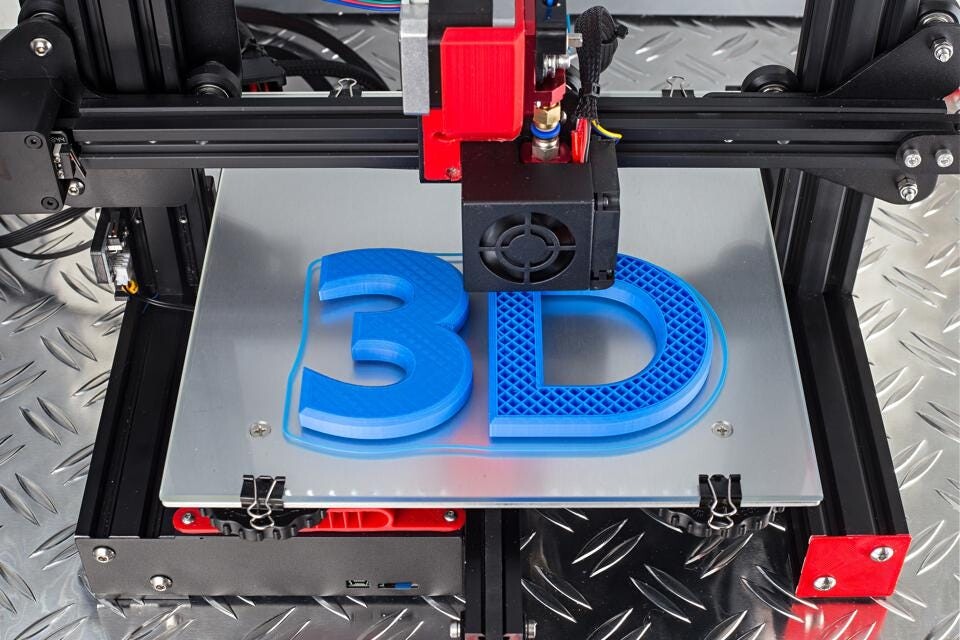

3D printing, or additive manufacturing, is revolutionizing various industries by offering unprecedented opportunities and efficiencies. This technology involves creating three-dimensional objects by layering materials based on digital models. As it becomes increasingly accessible and advanced, 3D printing is making significant impacts across diverse fields. Here, we explore the myriad benefits of 3D printing, highlighting its transformative potential.

Customization and Personalization

One of the most notable benefits of 3D printing is its ability to offer highly customized and personalized products. Unlike traditional manufacturing methods, which often require molds and tooling, 3D printing enables the creation of bespoke items with intricate details tailored to individual specifications. This capability is particularly advantageous in industries such as healthcare, where custom prosthetics and dental implants can be precisely designed to fit each patient’s unique anatomy. The ability to easily adjust designs without the need for expensive retooling also means that consumers can enjoy products that are specifically suited to their preferences, whether it’s a custom phone case or personalized jewelry.

Cost Efficiency

3D printing is proving to be a cost-effective alternative to traditional manufacturing processes. For small-scale production runs or prototyping, the absence of expensive molds and tooling can significantly reduce costs. Traditional manufacturing often involves substantial upfront investments in equipment and setup, whereas 3D printing requires only a digital model and the printing materials. Additionally, the technology minimizes material waste, as objects are built layer by layer from the ground up, using only the necessary amount of material. This not only reduces costs but also contributes to more sustainable manufacturing practices.

Rapid Prototyping and Innovation

In the world of product development, speed and flexibility are crucial. 3D printing accelerates the prototyping process, allowing designers and engineers to quickly create and test prototypes. This rapid iteration cycle can lead to faster innovation, as designers can make adjustments to their models and print updated versions in a matter of hours. This capability streamlines the development process, enabling faster time-to-market for new products and allowing companies to respond more agilely to market demands and technological advancements.

Complex Geometries and Advanced Designs

Traditional manufacturing techniques often face limitations when it comes to producing complex geometries and intricate designs. 3D printing, however, excels in creating detailed and complex structures that would be challenging or impossible to achieve with conventional methods. This includes the ability to produce lightweight components with optimized internal structures, such as lattice frameworks, which can enhance performance and reduce material usage. The freedom to create intricate designs also opens up new possibilities for innovation in fields such as aerospace, automotive, and architecture, where advanced design and functionality are crucial.

On-Demand Production and Supply Chain Efficiency

The concept of on-demand production is one of the key advantages of 3D printing. Instead of manufacturing large quantities of items and storing them, businesses can produce parts and products as needed. This on-demand approach reduces the need for inventory storage and minimizes the risk of overproduction. Additionally, 3D printing can facilitate localized production, allowing for goods to be produced closer to their end-users. This can lead to more efficient supply chains, reduced shipping times, and lower transportation costs, ultimately enhancing overall operational efficiency.

Educational and Research Advancements

In the educational sector, 3D printing is transforming the way students and researchers approach problem-solving and design. Educational institutions are increasingly incorporating 3D printing into their curricula, providing students with hands-on experience in creating physical models and prototypes. This practical experience enhances understanding and fosters creativity. In research, 3D printing enables scientists to experiment with new materials and designs, accelerating discoveries and innovations across various fields, from biomedical research to materials science.

Environmental Benefits

The environmental impact of manufacturing is a growing concern, and 3D printing offers several advantages in this area. By reducing material waste through its additive process, 3D printing contributes to more sustainable manufacturing practices. Additionally, the ability to produce items on-demand can decrease the need for excess inventory and reduce the carbon footprint associated with transportation and warehousing. As the technology continues to advance, it is expected to further contribute to eco-friendly practices and the development of sustainable materials.

Conclusion

The benefits of 3D printing extend across numerous industries, offering solutions that enhance customization, reduce costs, speed up prototyping, and enable complex designs. Its potential to streamline supply chains, advance education and research, and promote environmental sustainability underscores its transformative impact. As 3D printing technology continues to evolve, its role in shaping the future of manufacturing and various other fields will undoubtedly grow, unlocking new possibilities and driving innovation.